Owl Vans started in the garage of Founder and CEO, John Willenborg's home — or more accurately, "really kind of the alley between our houses, so the grinding and the welding was quite loud," John explains. "I’m sure that it was very annoying to my neighbors."

Early on in life, John felt compelled to follow the traditional route for school and business, but he continually came back to his true passion: working with his hands and designing innovative products. Even with his early hand-built Sprinter carrier designs, he was very comfortable sourcing, grinding and welding, in part due to his history with product design and fabrication — John's former company designed, manufactured, and supplied products direct to the Apple Store, but even before that, he started learning welding and fabricating at a young age.

My uncle was a Navy Seal turned underwater welder. I spent summers with him working and helping him as his apprentice. I didn’t get paid anything — I just did it because I loved working with my hands, and I wanted to learn everything as best as I could. And talk about work ethic — go be an apprentice to a Navy Seal, and you’ll very quickly learn that your best is not good enough.

Combining his manufacturing knowledge and personal love for outdoor activities like biking, motorcycle racing, and camping, John seized the opportune moment in his life — a transitional phase after selling his company — to begin meticulously designing and handcrafting his first carriers from the ground up. There was no goal to launch a company then, just a determination to reinvent the "clunky and expensive" Sprinter tire carriers on the market at the time, lifting the tire carrier up higher and allowing it to swing with the door — a first in carrier design.

I built those for my vans, and used them for many, many years, and would continually get asked "where did I get that, where did I buy it" and "will you make me some?" Eventually, I had enough people asking me, I thought "technically, I’m not doing anything right now, so why don’t I build some and see what people think."

Through his lively interactions and discussions on well-known Sprinter Forums and showcasing his own carrier creation on his YouTube channel, he gathered motivating input and support from the Sprinter community. Individuals often provided their own experiences and complaints about stock Sprinter spare tire mounts, asking John to solve issues like, "can it mount lower for easier on and off?" and "what about a way to lock it so someone can’t steal my wheel?"

He took their feedback and personal experiences, and moved forward, building ten units and offering them for sale on Sprinter forums.

All ten sold out in an hour so I thought why don’t I build ten more, and they all sold out overnight, so at that very moment I said, "there is absolutely a hunger in the market for new and improved gear and innovative products."

From that day forward we’ve never looked back.

From Patiently Hand-Built to Precision-Built Owl Products

Each one of the original 20+ Owl carriers was like an original work of art, made entirely by John himself. Throughout the prototyping phase, he found himself taking long bike rides daily and each ride would help him work through his design process. "Those 2-3 hours on that ride, all I would do is take the problem and roll it over in my head. ‘How do I fix this problem I’m running into, what if I do it this way, what if I invert this, what if I bend it this way?'" he explains.

In the beginning, he spent an exhausting amount of time troubleshooting designs and tediously bending aluminum by hand using a long poll for leverage, ratcheting it back and forth to create his first carriers.

Originally, for hubs, I would buy flat discs on eBay. I had a template and hole puncture, and I would punch these holes out by hand. I would have to throw about 50% away because the punch would be off by a millimeter and wouldn’t line up with the wheel. [I had] very manual processes — no two carriers were identical back then because [even though] I had jigs and I did my best to make them as identical as possible, when you’re doing things by hand there’s always a little bit of variation...

I look back on that fondly because at this point there is very little of that.

Today, Owl Vans can replicate their own product to perfection — down to the millimeter.

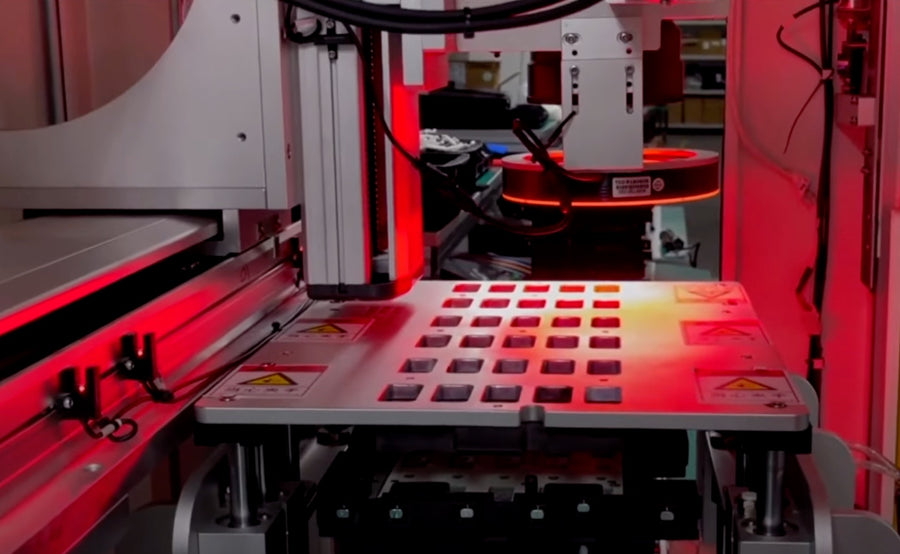

Using highly precise laser scanners and CAD designs to build their prototypes. Once prototyped, products are thoroughly tested during development to ensure correct design, manufacturing, strength, and durability. The Owl Vans team also designs for aesthetics, skillfully creating products that enhance the van's design with tested, well-designed proportions as well as necessary functionality. John says they can build with such high quality thanks to having access to the best manufacturing.

Most Owl parts now are either "laser cut, machine bent or robotically welded." They don't simplify their product designs; they refine them.

We’ve gone from a manual, bespoke, handmade product — to high volume and high precision product.

We order in economies of scale now. We do full mill runs from aluminum tube manufacturers, so we’re actually getting our own orders in our own alloys made by aluminum smelters. They make the product specifically for us, so it is all domestically sourced aluminum and different from what you can buy from your regular metal seller [which] doesn’t bend properly, doesn’t hold up to rigorous off-road use properly, and doesn’t weld properly. A lot goes into what we do that people will never know, and I'm okay with that.

What's Next for Owl?

Exceptional design and manufacturing meet premium materials — that's Owl at its core. Beyond the awesome gear is an incredible story of Owl's unwavering commitment and love for the van experience and industry.

Owl Vans has not only redefined exterior accessories but continues to lead the van industry with design innovations and top-quality manufacturing. They're driven to create products they are truly satisfied with -- that's it.

These vans are cool, and we don’t want to detract from that — we want to add to that. The aesthetics are a big part of what we do.

We don’t sit down to say, "Here’s the industry, here’s the holes, here’s the budget." We’re much more like, "Hey, you know what would be cool, if I had the ability to do this: ____" and then if I build it and think it looks cool, our customers tend to feel the same.

Owl Vans' backbone is all about community and has been from the beginning. Customer and community feedback has continued to improve their designs and product range. Coming back to the actual van users, Owl develops products that solve problems because when you use these parts every day and in all types of places you know very well what is great and what is severally lacking with product design and real-world function.

From concept to launch, Owl Vans' new product development is never hindered by lack of inspiration or ability. Their team has simply had to fight to keep up with all the demand for current products. John says before now it was increasingly difficult to manage new product manufacturing with their consistently high demand plus recent disruptions while moving into a larger warehouse space in Arizona, but they are now fully in stock and ready to continue with product designs in full scale.

In contrast, many of their most popular product designs to this day were completed in the first 90 days of opening shop in what John describes as a “glorified storage unit.”

At the time I had one product, a tire carrier for the NCV3. From that first day I opened shop we went from one product to having: tire carrier, high mount roof carrier, box carrier, ladder/tire, B2, and sherpa — all designed all within the first 90 days that we existed. Those designs that are still our most popular products were all in those first three months.

All we could do is hang on with our fingernails with the demand.

Currently, they’re working on several new product designs, and John still enjoys being fully involved with Owl Vans product development process.

If I decide I want to make a part, I physically go out and manually create something that initially solves the functions, and it’s usually pretty heinous, and we go from there as far as refining it.

First, meeting the functional need, and then once we meet the functional need, we meet the aesthetic need.

Their latest product developments include Transit carrier upgrades and Transit suspension upgrades, but John says he is most excited to release their newest front bumper for ProMaster vans. You read that right — a perfectly sized front bumper, giving your ProMaster van a big refresh and boost in safety. Plus, watch for more designs on the way from Owl for ProMaster vans — don't miss out!

Check out Owl Vans Products Available Now

1. Owl Vans Sprinter (2019+) Aluminum Expedition Tire Carrier

2. Owl Vans Ladder + Tire Carrier - Sprinter VS30 (2019+)

3. Owl Vans Expedition Box

4. Owl Vans B2 Bike Carrier - Sprinter VS30 (2019+)

4. Owl Vans B2 Bike Carrier - Sprinter VS30 (2019+)

5. Owl Vans 2019+Sprinter Aluminum Hitch Step

6. Owl Van Mojo Sprinter Wheels 17” 8” (5 Wheel Bundle)

7. Owl Vans Talon SPRINTER Wheels 17” 8” (5 Wheel Bundle)

8. Owl Vans Talon TRANSIT Wheels 17” 8” (5 Wheel Bundle)

9. Owl Vans Monster Box (XL Cargo Box)

10. Owl Vans Horn Upgrade (Super Bass)

11. Owl Vans Sprinter Hood Strut Kit